Click the button to start reading

Time Saving Secrets That Will Make You Cheer: How to Use the Critical Path Analysis in Project Management

When you’ve got a project that’s brimming with hangups, where team members quit, materials arrive late and bottlenecks delay production, it’s really easy to throw money at it with the hope to speed things up. This may provide some momentary relief as the clock ticks and the deadline looms nearer.

As so many have learned the hard way, however, haphazard spending doesn’t make much of a difference. More often than not, the project is still delayed, with the added bonus of wasted money, labor and materials.

This may easily leave one wondering about an effective plan of attack. How does a complex project meet a fixed deadline, yet still remain within its planned scope and budget?

Way back in the 1950s, a think tank of engineers devised a method that addresses this conundrum. It identifies where to focus energy and resources in a project, and what areas require less attention. Plus, it also pinpoints where a project can create efficiencies in order to speed up its schedule and get things back on track.

This discovery is known as the critical path analysis. Let’s take a look at this method, discuss how to use it strategically and evaluate how it compares to similar project management tools.

A Definition of the Critical Path Method

The critical path method (CPM) provides an estimate for a project’s duration, as well as determines the slack time in individual activities. It achieves this by breaking a project down into individual activities, then evaluating the resources and duration of each, as well as the relationships between them.

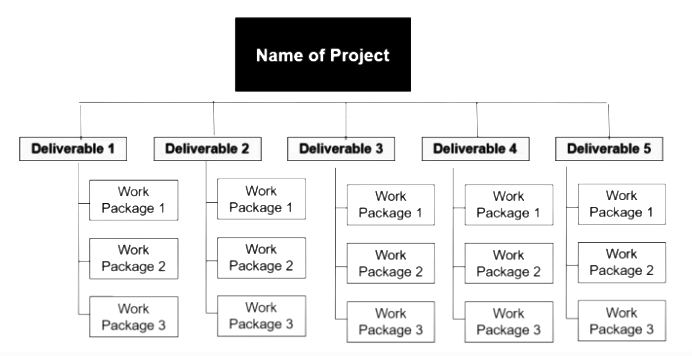

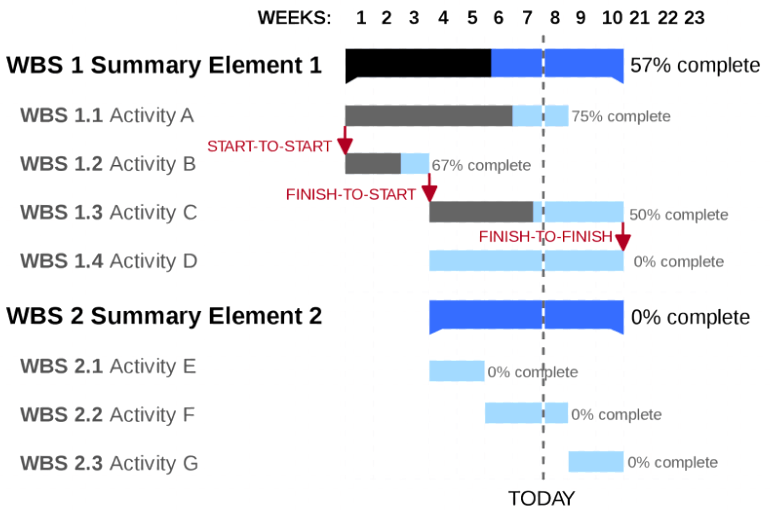

The most basic component of the critical path method is the collection of all of the activities required to complete the entire project. Generally, these activities are determined by breaking high-level requirements into increasingly smaller batches of work using a work breakdown structure. For example, in a home remodel a high level requirement might be to repair the deck. This requirement could be broken down into: clean the deck, replace old wood and seal the deck.

Next, the individual activities are studied to determine their sequence and dependencies. A dependency is a relationship between two activities that determines when one activity can begin. Take, for example, the project of decorating a room, where two activities are to paint the walls and to display artwork on the walls. These activities are dependent, as the walls must be painted before the artwork can be displayed.

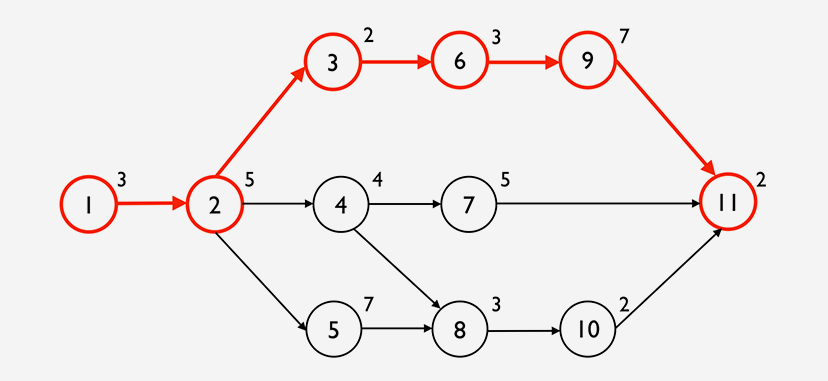

The sequence and dependencies of all the activities are arranged in a network diagram, or precedence network. The project management glossary defines precedence network as a diagram that “visually indicates relationships between project activities. Boxes and links are used to represent activities and activity relationships. Precedence networks also detail the time relationships and constraints associated with activities.”

The network uses arrows to indicate relationships between activities. Each activity is also assigned an estimate of the resources required (the labor, materials, cost and facilities).

In some projects, activities cannot be parsed out and separated nicely and neatly. It’s still possible to use the CPM in these instances. Rather than boxes representing each step in workflow, arrows are used instead. In the words of James Kelley, an engineer who developed the critical path method,

“Draw an arrow for each job and write its name, duration and resources on the convenient line formed by the arrow’s shaft. If one job is the direct predecessor of another, connect the head of the first to the tail of the second.”

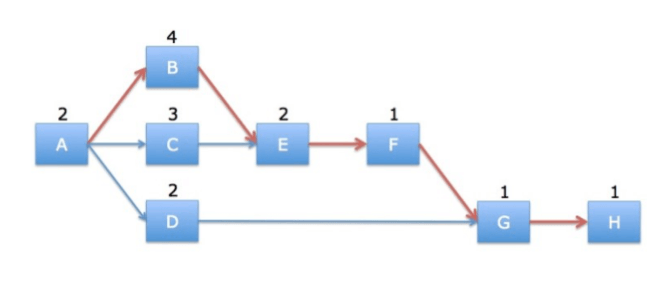

The longest path in the network diagram is its critical path. As its name suggests, the critical path is the sequence of activities that determines the duration of the project, and so it merits the most attention. In the image above, the sequence A, B, E, F, G, and H has the largest sum (where numbers are a measure of time), making it the critical path.

The diagram also indicates any float or slack within activities that are not on the critical path. Float and slack measure an activity’s wiggle room, or the amount of time it can be delayed without delaying the entire project. In the example above, activity D takes two units of time to complete, during the same window as activities C, E and F, which take six units of time collectively. As two from six is four, activity D, then, has four units of slack.

The critical path analysis is helpful in any project manager’s toolbox. It allows for prudent resource allocation, as it indicates where to focus resources in order to keep a project on track. It also improves a risk management plan, as again, it indicates the critical activities that require extra attention. And finally, it generally saves time, as it forces a team to think a project through to completion, and highlights areas that need extra attention at the get-go.

The History of the Critical Path Method

The critical path method has its origins at the duPont de Nemours company, which started in 1802 as a gunpowder manufacturer. DuPont is noted for its rigorous research department, which in the 1900s invented and manufactured nylon, Teflon and synthetic rubber.

In the late 1950s, its internal think tank, the Integrated Engineering Control Group, was assigned the task of reducing expenditures while maintaining the current output. The assignment primarily fell to James Kelley, Morgan Walker and John Sayer. Over a period of 27 months, the trio focused on planning, scheduling and estimating as the means to create efficiencies within the operations.

They proceeded with the assignment by breaking work into individual activities, and assigning it “man days” and then an overall cost by using the employees’ salaries. Then they looked at the entire work process in order to establish sequence between the activities. They soon came to appreciate the ardor of compiling this data manually, and so leased a computer from Remington Rand Univac in Philadelphia. Fortunately, Walker proved a huge asset in this regard, as his skill set included design, construction and computers to boot.

Breaking a project down required making simplifications. It assumed one duration for an activity. It did not distinguish between direct and indirect costs, but assigned an activity one overall cost. It also assumed that expediting an activity increased the cost.

With its compilation of activities, the trio determined which activities it could expedite by adding more resources. To their great surprise, they discovered that expediting certain activities reduced a workflow significantly, with only marginal increases to the overall cost.

“…by cutting average turnaround downtime by some 25% through CPM, production to sales was increased enough in the first year to more than underwrite the CPM development,” writes James Kelley.

Arriving at these conclusions required complex algorithms and algebra, which the trio computed on a UNIVAC I program that listed up to 200 separate activities. With their newfound theory, they honed the algorithm, and started applying the system to small projects.

CPM’s initial applications encountered resistance to change. Listing equipment, segregating activities and estimating durations weren’t part of the current processes for managers and engineers. It took as much as two months to compile the initial inputs needed to create the network diagram and determine the critical path.

But the method did catch on. In 1959, they taught CPM at a five-day workshop in Philadelphia. Participants returned to their businesses, applied the principles, and started requesting more workshops and training.

Over the ensuing decades CPM spread gradually, but its complexity prevented widespread adoption. A manual application was only possible for simple projects with only a few activities. In the 1980s, the availability of project management software allowed many organizations to utilize the method.

Although historically CPM was used to revive a sluggish project, it’s now a fundamental component to project planning, as implicit as the theory of constraints or Gantt charts.

The Six Steps to Calculate the Critical Path

Most projects have hundreds if not thousands of individual tasks, and so a calculation of the CPM requires software. A manual development of a network diagram is only possible with very simple projects. However, whether manual or automatic, the process is the same, and it’s fairly straightforward. Here are the six essential steps to calculating a project’s critical path.

1) Identify the Objective

The CPM begins with a summary of the project’s central objective, the completion date and the high-level requirements. For example, if the project is a wedding reception, the first step is to gather key details such as the date, and the central components of the reception, such as a dinner and a dance.

2) Break Down Requirements

The next step is to break the high-level requirements into small independent activities. This is effectively completed with a work breakdown structure.

A work breakdown structure breaks high level requirements into increasingly smaller work packages. For example, at a wedding reception, the requirement for “dinner” would break down into the tasks of reserving a space and tables, hiring a catering company and deciding on a meal.

3) Estimate Duration and Map Out Dependencies

When all the activities are laid out, the next step is to estimate how long each should take, clarify the sequence, and identify dependencies between activities. In a manual calculation, it’s helpful to write each task onto 3×5 index cards.

With a one-off project such as a wedding reception, the duration is an estimate. However, it’s helpful to refer to similar projects or to make an educated guess based on research. In complex projects that require many varied skills, gathering input from key stakeholders and subject matter experts ensures the estimates are accurate.

Identifying dependencies means taking a broad view of the entire project, and noting where activities link together and how they contribute to the completion of the entire project. For example, with a wedding reception, choosing a venue must be completed before sending out invitations. These two tasks have hard dependencies, as one one must occur before the other.

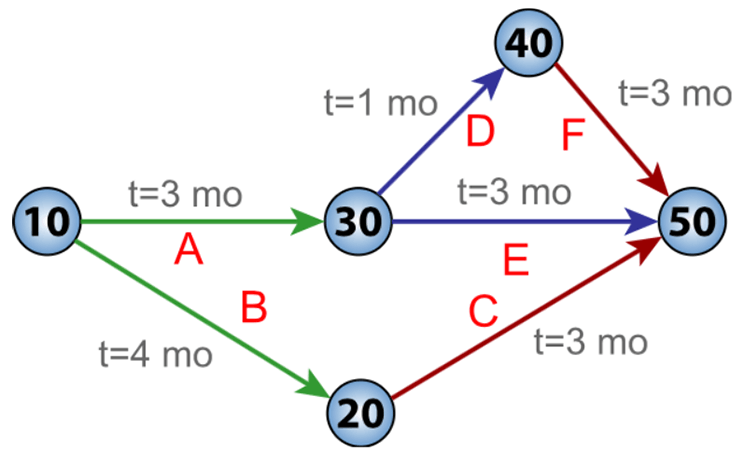

4) Create a Network Diagram

With the sequence and the dependencies clarified, the next step is to arrange all the activities together into a network diagram, connecting sequences with arrows. In the network diagram, each high level requirement has its own sequence of tasks, and oftentimes these tasks overlap or are dependent on one another.

For example, in planning a wedding, one high level requirement is sending out invitations. The first step is to determine the guest list, then create the invitations, then mail everything out. The completion of this activity, as discussed, is dependent first on selecting a venue for the reception. In addition to lengthy activities with multiple steps, a project has several one-offs, such as hiring a photographer for a wedding reception.

5) Calculate the Critical Path

With all of the activities laid out and connected sequentially with arrows, calculating the critical path simply means adding up the sequences for each path and determining the path with the largest value.

6) Calculate Slack

A final step is to calculate the slack associated with each non-critical activity. The slack for a non-critical path is its own length subtracted from the length of the critical path.

For example, say the wedding reception takes 12 weeks to plan, and hiring the photographer, a one-off activity, is expected to take three weeks. A backward pass subtracts 3 from 12, meaning that it can be started as late as week nine in order for the project to stay on track.

These six steps outline the central components of calculating a critical path. As mentioned, when a project involves hundreds of steps, the process cannot be calculated manually. However, sometimes just completing these simple steps yields insight sufficient to reduce the project’s overall expenditures. As James Kelly writes,

“If one does no more than intelligently draw the network and calculate the early and late times and float, one has 90% of the value to be gained from using network methods for project planning and scheduling.”

Additionally, the critical path can change. Projects rarely proceed according to a precise plan, and so delays or an inaccurate estimate may cause the critical path to shift. The network diagram, then, is something to monitor closely during a project’s execution, and to update when changes occur.

Techniques to Compress a Critical Path

Often, a critical path can be decreased with resource allocation and schedule compression techniques. A schedule compression technique is just like it sounds. It’s a method for decreasing the length of time it takes to complete a project. Note that a schedule compression technique simply decreases time; it does not change the scope. The same amount of work is completed, but the project’s duration, its critical path, is decreased.

Two popular schedule compression techniques are known as crashing and fast tracking. Essentially, they entail finding a more expensive yet faster option for completing a task, or completing two normally sequential tasks at the same time.

To fast track means to take two sequential activities on a critical path and arrange them parallel to one another. Rather than complete one activity after the other, the two activities are completed at the same time.

For example, consider the project of making breakfast, something we all do every morning. Say the normal routine is to toast bread and butter it, then boil water for tea. Fast tracking the two activities means boiling water at the same time that the bread is toasting.

Fast tracking is simple and intuitive in this example, but it doesn’t work when two tasks have hard dependencies. This means that one task must be completed before a second task can begin. For example, with breakfast, you cannot steep a tea bag as you boil water. One task must be completed before the other.

Crashing is a schedule compression technique of using additional resources in order to shorten the duration of an activity. Let’s say you’re hosting guests, and need to fry eggs and toast bagels for six people in the morning. Your toaster has the capacity to toast two slices of bread at a time. Crashing the activity means purchasing additional toasters to speed up the task of toasting bagels.

Crashing carefully considers the relative cost increase of various activities on the critical path in order to determine the thriftiest way to shorten the schedule. For example, if the toasters cost $75 each, yet an additional frying pan only costs $10, you’d choose to crash the task of frying the eggs rather than the toast.

Crashing, as you can see, usually means increasing the cost of an activity in order to complete something faster. However, as Kelly and Walker discovered in the development of the CPM, oftentimes the efficiency created by crashing a task actually decreases the project’s overall cost.

Crashing doesn’t always work. The duration of some projects cannot be compressed with the addition of more resources. To put it humorously, nine women cannot deliver a baby in one month.

Although both these techniques shorten a schedule, they also expose the project to risk. Crashing, as discussed, increases cost, and so it needs to be used strategically. In the interest of saving time, a project manager may crash several activities, and cause the project to go over budget.

Fast tracking poses a few more problems than crashing. Sometimes it places two tasks in parallel that ideally should be performed in sequence, and this may lead to rework. Take, for example, the project of planning a party, with the two sequential tasks selecting a venue then hiring a deejay. Completing the two tasks in parallel may lead to complications. Maybe the deejay doesn’t have the sound equipment needed for the selected venue, and someone else needs to be found instead.

Seven Advantages of the Critical Path Method

It’s no accident that the critical path method has grown from an obscure method at DuPont into a popular method incorporated into every project management school’s curriculum. It sprinkles magic powder over a project, so much so that many project managers utilize it with every go-around. Here are some of the CPM’s central benefits.

1. Calculates a Realistic Timeline

It’s easy to set an end date for a big project. “This closet is going to be organized by the end of the week,” we might tell ourselves. While instead, the project drags on for a month, in large part because many of its smaller activities take much longer than we anticipated.

The critical path method does away with this sloppy estimating. It delves into each component of the project, and comes up with a realistic time estimate for each. This results in a timeline you can really lean in on.

This technique is particularly helpful for projects with hard and fast deadlines, such as events. It ensures that all the necessary tasks have been completed before the event occurs.

2. Identifies Dependencies

When all the individual activities in a project are written up on 3×5 cards and laid out on a table, it’s easy to connect dots and establish connections. Understanding dependencies clarifies the sequence of tasks. When planning an event, for example, the venue, date, and time must be chosen before any promotions occur.

Identifying dependencies also assists with risk management. It highlights the critical activities the project depends on in order to move things forward, and focuses risk management strategies around them.

3. Creates a Powerful Visual of the Entire Project

The network diagram lays out every component of a project, from start to finish, in a coherent diagram that’s reasonably easy to grasp. When presented or distributed to stakeholders and subject matter experts during the planning stage, it gets everyone onto the same page, and creates an opportunity to provide critical feedback and identify shortcomings.

4. Provides a Planning Tool

So often projects begin with a foggy “let’s do this” mentality. The project is executed without much of a plan and a team gets itself to a point of no return. At this point, it’s not uncommon to encounter major roadblocks. In a remodel project, perhaps, walls are torn down and flooring is ripped up before the homeowner realizes he doesn’t have the budget to replace them.

The critical path method avoids this dead-end trap. It thinks everything out in advance and puts a plan in place. It identifies dependencies, estimates costs and calculates duration. This careful, deliberate thinking determines if a project is tenable and provides a clear path all the way to the project’s completion.

5. Provides Focus

It’s easy to waste time in a project fixing things that don’t need to be fixed. For example, maybe some materials don’t arrive in time, and the team scurries and frets to find a replacement. However, if the materials are for a non-critical activity, it may well be that the delay won’t impact the overall timeline.

The critical path provides a healthy focus to a project. It highlights those activities that need extra TLC, as well as those non-critical activities that can be overlooked for a time.

6. Identifies Activities With Float

The critical path method not only identifies non-critical activities, it also calculates the float for each of these activities. This knowledge, again, allows a team to put time and energy into the things that matter, and to know how long to delay a non-critical activity.

7. Uses Resources Wisely

The CPM conserves resources. Rather than blindly throwing resources at a project with the hope to speed things up, it identifies those specific activities to focus on in order to save time and money.

With all these benefits, it’s no surprise that every certified project manager understands how to use the CPM. Although the method takes some work to apply, it’s a planning and execution tool that many project managers keep in their arsenal for good reason.

4 Disadvantages of the Critical Path Method

At the same time, the critical path analysis isn’t the be-all and end-all. Although an excellent method, it cannot be used in isolation. When applied to a project, it’s necessary to understand the limitations of the CPM and of network diagrams in general.

1. Cannot Handle Complexity

The CPM falls flat in a complex project with thousands of interrelated activities. In this instance it’s certainly not possible to create a network diagram manually. Even with a sophisticated software, the simplifications implicit in the method make it ineffective in calculating dependable estimates.

2. Makes Many Assumptions

The critical path method is brilliant in its simplicity. But this simplicity means assuming only one value for both the duration and the cost of an activity. It doesn’t consider direct or indirect costs, or longer or shorter durations.

This over-simplification may well lead to inaccuracies, particularly in a project with many unknowns. If an activity is assigned an inaccurate estimate, it can throw off the entire diagram, and the project manager ends up focusing on the wrong tasks and assigning slack in the wrong places.

3. Requires Upfront Work

Creating a network diagram and determining the critical path means looking at every step in the entire project. Generally, this requires knowledge well beyond one or two people on the planning committee. In order to be accurate, it requires input from many stakeholders, skilled team members and subject matter experts.

Gathering all of this input is time consuming and sometimes just not possible during a short planning period, resulting in a weak network diagram that doesn’t serve as a powerful planning tool.

4. Requires Rework

As every project manager knows well, a project almost always changes during execution, even with an excellent plan. And any significant changes in a project’s scope or requirements means that the entire network diagram must be redrawn. Even small delays in tasks can change the critical path.

This re-work is time consuming, making the CPM so labor-intensive that much of a team’s energy is put into working then reworking the diagram rather than actually doing the project.

As you can see, the critical path method isn’t an end in itself. Although it provides key benefits, it’s a tool that’s best complemented with other methods in order to properly estimate a schedule and allocate resources.

In projects with changing requirements late in development, the limitations of the network diagram may even make it a no-go. Projects that incorporate an agile methodology, for example, welcome change. In this instance, the CMP constantly needs to be worked and re-worked, making it too time consuming to be worthwhile.

The nature of a project, then, determines whether or not to use the CPM. It makes a lot of sense in a project with many up-front costs, clear deliverables, and a fixed end-date. In a project where the requirements are subject to change, the CPM may be something to shy away from.

CPM Versus the Critical Chain Method

The critical path method is one of many techniques utilized by project managers to assist with end-to-end project management. Another popular tool is the critical chain method. Like CPM, the critical chain method yields a more efficient work process and conserves resources.

The critical chain method originated out of Eli Goldratt’s 1997 book, Critical Chain. It leans heavily on the theory of constraints Goldratt developed in his 1984 book, The Goal. The theory of constraints is a manufacturing principle that seeks to eliminate bottlenecks and create a more efficient workflow. It constructs an entire workflow around the slowest steps in the process by placing extra resources at these steps.

Whereas the CPM is activity focused, the critical chain method is heavily resource focused. It’s closely related to capacity management and focuses on building idle capacity at the slowest places in a workflow. Resource leveling, which distributes resources evenly along a work process, is central to the method. The critical chain is determined by the longest sequence after all resources have been assigned to tasks and then leveled.

Here are some key differences between the critical path and critical chain methods:

- The critical chain doesn’t identify dependencies between activities.

- The critical chain doesn’t look for an optimal work path like the CPM. Rather, it finds a “good enough” work system.

- Whereas the CPM is determined from a static and fixed diagram, the critical path is a dynamic process, where change is welcome and anticipated.

- The CPM focuses on activity completion, whereas the critical chain monitors progress by evaluating resource consumption.

The critical chain provides these benefits to a project:

- The critical chain uses a pull workflow, meaning that tasks begin just as the previous task is completed. This eliminates “student syndrome,” or the tendency to put something off until the last possible moment.

- The critical chain encourages swarming in order to complete a task before moving onto the next thing. This hyper-focus on one activity reduces a tendency to task switch or multi-task, two processes that slow a project down.

- Activities in the critical chain don’t have fixed start and end times, which reduces a phenomenon known as Parkinson’s Law, where the length of a task is determined by how much time is allowed for it.

- Unlike CPM, critical chain considers both short and late start times for activities, which yields more realistic estimates.

Both the critical path and the critical chain develop out of a work breakdown structure. The critical path method is great as a planning tool, as it looks at a project in broad overview and thinks everything through. The critical chain, on the other hand, assists with the project execution. It creates efficiencies in workflows. A work process with huge bottlenecks might benefit more from the critical chain method over the CPM.

CPM Versus PERT (Program Evaluation Review Technique)

PERT is another method for calculating project duration. In many respects it’s almost identical to the CPM. PERT is an acronym that stands for program evaluation review technique.

Although PERT and the CPM evolved around the exact same time, they developed independently from one another. PERT was developed as a planning tool for the U.S. Navy’s Polaris nuclear submarine project in 1957. The navy propogated the method in a publication the following year. Since its development, it’s been used as a planning tool within many industries and for many events, including the 1968 Olympic Games.

The work breakdown structure developed out of PERT, as a means to parse a project into individual units of work. The work breakdown structure is a hierarchical grid that breaks high-level requirements into increasingly smaller units of work.

Here are some key differences between PERT and the critical path method:

- PERT primarily focuses on activity duration, whereas CPM looks at both the duration and cost of an activity.

- PERT assigns each activity four time estimates (optimistic, expected, most likely and pessimistic) whereas the CPM assigns only one. This difference ranks PERT above the CPM in projects with a lot of uncertainty around duration.

PERT provides many benefits, many of which are similar to the critical path method:

- A central benefit is that PERT lays out an entire project from beginning to end, and identifies a clear completion date. For this reason, it’s commonly utilized in event planning.

- PERT evaluates all the processes and activities in a project before execution. It highlights those activities and processes that require extra attention, and allows a project to proceed as scheduled.

- PERT identifies a project’s critical path.

- Just like the critical path method, it reveals the slack in certain activities and also identifies dependencies.

- It provides a powerful visual display of the entire project that’s useful for collaboration and decision making.

PERT is complementary to and in many ways almost interchangeable with the critical path method. However, PERT is the preferred method in a one-off project with a fixed completion date, such as planning an event.

However, neither method addresses bottlenecks or analyzes workflows as a means to create efficiencies in a project. For this reason, they serve as excellent planning tools but not stand-alone methods.

CPM Versus Gantt Charts

The Gantt chart is another popular project scheduling technique. Rather than creating a diagram like the CPM, it lays out a project and all of its various tasks in a bar chart. The Gantt chart was developed by Henry Gantt around 1910 to use as an operations tool within his company. He wished to identify the productivity levels between his employees.

The Gantt chart achieves many of the same ends as the CPM, but by different means. It’s a bar chart that lists a project’s tasks on a vertical axis, and time on the horizontal. The chart notes interdependencies between activities, and each task is sequenced in relation to other dependent tasks.

The visualization of a project was novel at the turn of the century, and many adopted the method. Gantt charts were used in World War I and with the Soviet Union’s economic planning. However, Gantt charts were cumbersome to create and difficult to adjust as a project changed. The availability of project management softwares in the 1980s made Gantt charts easy to create and adjust. Since then, they have become almost ubiquitous in project management. However, a Gantt chart’s inflexible approach to project management makes it undesirable to agile enthusiasts.

Here are some key differences between Gantt charts and CPM:

- The Gantt chart does acknowledge dependencies, but not so clearly as the critical path method.

- The Gantt chart is primarily a scheduling tool. It does not identify the resources utilized in activities.

- The Gantt chart does not identify a critical path, making it unclear where to utilize schedule compression techniques and so shorten a project’s schedule.

A Gantt chart provides many of the same benefits and challenges as CPM:

- It identifies slack and dependencies within activities.

- A Gantt chart is easy to understand, perhaps even more so than a network diagram. It’s also a powerful visual. For these reasons, it’s an effective planning tool, allowing many stakeholders to grasp the overall plan and offer expert opinions.

- Like the critical path method, a Gantt chart needs to be redrafted when requirements change or scope increases. This is particularly cumbersome when it’s drafted manually. In projects with many changes, or where change is fundamental to the process, Gantt charts quickly become useless during the execution phase.

Like the CPM, the Gantt chart serves as an effective scheduling tool. However, due to its many limitations, it certainly shouldn’t be used exclusively, but along with other project management tools.

Conclusion

When a project struggles with keeping to a timeline or staying within a budget, the critical path method may be just the solution.

The CPM is a visual display of a project that provides a plan of attack that holds the reins on a project’s timeline, cost, and resource consumption. It’s particularly effective in projects with hard and fast deadlines.

CPM breaks a project down into individual activities, and constructs a diagram that clarifies the sequence and dependency of each activity. The method promises to save time and resources.

Although the CPM has become a cornerstone to project management since its inception six decades ago, the method has drawbacks. Its greatest limitation is that it creates a fixed plan for a project, and it’s hard to utilize if a project changes during execution. In projects where requirements and scope changes, it’s best as more of a reference tool than a guide.

If you’ve found that your current project planning method wastes time and results in a poor deliverable, then the CPM may provide just the solution you need to turn things around.